In the mid nineteen-forties, Jackson Construction Company purchased some land in the

Echols area and walked a Marion 40D Shovel from Centertown to the new mine. This small

company was non-union and before any coal could be mined, the United Mine Workers

Of America established a "Picket Line" and the mine was shut down. This "Strike"

lasted some nine months and Jackson Construction Company would not agree to union

representation and sold the property to Kessler Brothers Coal Company. Kessler

Brothers Coal Company signed an agreement with the UMWA, but before very much coal

could be mined, sold the new Ken Mines to Peabody Coal Company. In 1946 Peabody Coal

Company became established in Ohio County and signed an agreement with the United

Mine Workers Of America. Now, a new era began and coal mining at the Ken Mine could

finally start.

"Strip" mining was new to Ohio County in the nineteen forties. Although there were

a few "Strip Mines" in Hopkins County and other Western Kentucky Counties, Strip

Mining was mostly an idea and not very practical. In this time frame, 20th Century

Mines had a small Strip Mines in operation near Echols and there was a small Strip

Mines in operation near McHenry. "Underground Mining" was the norm though, and most

of the mines just did not consider mining the coal using the "Strip Mine" process.

This process consist of moving all of the material (Overburden) from the top of the

coal with a "Stripper" or other "Earth Moving" machines. Once the "Overburden" was

removed, the coal would be loaded into large trucks with smaller versions of the

"Stripper". These "Loaders" were similar in appearance to the "Strippers", but on

a much smaller scale. The depth of the overburden that could be moved, by a stripper,

depended on the ability of the "Stripper" to be able to find enough dumping room for

the overburden. This ability was determined by the length of the boom. In the late

forties and early fifties, there were not any huge strippers that could remove 100

Feet or so of overburden, simply because the stripper did not have the reach to pile

the overburden one hundred feet high. Thus. Underground Mining was the most popular

means of mining the coal. Some of the "Coal Reserves" at the Ken Mine was sitting

under "Dirt and Rock" twenty to a hundred feet deep. Until massive "Strippers" could

be built, most of the coal could not be mined by the "Strip Mine" process.

"Strippers" come in two basic forms, a "Shovel" and a "Dragline". About every miner

has an opinion on which type of stripper is the best and that probably depends somewhat

on the type and condition of the overburden to be removed. Peabody Coal Company had

a large variation of each type stripper, with Ken Mine operating a "Shovel" in one

pit and a "Dragline" in another pit. A "Shovel" uses the method where the digging

mechanism (Shovel) is attached directly to the "Boom". The "Shovel" is stationed

in the "Pit", and on top of the coal. It faces the highwall and removes the overburden

"Head On". It normally sits on four separate "Tracks" that act as the driving mechanism

to move the shovel. By the use of "Levers" the "Bucket" is moved into the overburden

and raised allowing the "Dirt and Rocks" to be scopped up and then, the loaded bucket

is swung around and the load is dumped on what is called the "Spoil" side. Ideally,

this process continues seven days a week, twenty-four hours a day.

"Draglines" are somewhat different than "Shovels". They have been in use for just

about as long as there have been motors. A dragline sits on what is called a "Tub",

and like the "Shovel", it must remain mostly level. To move a dragline, large "Pads"

or "Feet" are extended from each corner and toward the direction of the move. A "Lifting"

mechanism will raise the "Tub" a few inches off the ground and allow the machine to

move forward. The "Dragline" operates above the pit and on top of the "Overburden".

The "Bucket" is attached to the boom with cables that are used to raise, lower, pull

and dump the loaded bucket. The "Boom" extends out from the overburden and the "Bucket"

is lowered into the pit. The bucket is now pulled or "Dragged" toward the dragline,

filling up with "Dirt and Rocks". Then the digging end of the "Bucket" is raised a

little so as not to spill the contents. The entire "Bucket" is now raised and swung

to the "Spoil" side and dumped. This process, ideally, continues 24/7.

A "Strip" Mine can be a very large operation with large machines and a variety of

workers. Most strip mines cover hundreds of acres. The process of removing the coal

from the ground, to the last stages of shipping it to buyers can be a complicated

process. The "Pit" is probably the center of attention, as that is where the coal

is located and the job of the miners is to get this coal and transport it to a place

where it can be shipped to those that purchase the coal. From the pit, "Haul Roads"

are constantly being built to the "Processing Plant" or plants. The "Office" complex

is another "Center Of Activity", as plans for the mine operation are constantly being

changed and updated. The mine history, as well as the miners work activity must be

recorded, payrolls completed, equipment bought, sold and repaired. All types of

shipments in to the mine and out of the mine are processed through the office. The

"Garage" area and other workshops are usually contained in a central area and broken

equipment that can not be repaired in the field are brought to this busy work area.

In many cases, an "Underground" Mine will be located in a "Strip Mine" area. The

managers, foreman, other bosses, clerical workers, truck drivers, pit crews, welders,

electricians, etc, need a staging area or reporting area. To better facilitate this

type of operation, the employees are assigned to a certain group or a crew. For

instance, the electricians form the "Electrical Crew" and report, at the start of

the shift, to their shop. From here they are dispersed to where they are needed.

Special crews like the "Stripper Crew" or the "Loader Crew" consist of only a few

people and it is not uncommon for these crews to work together for ten years or so.

A bond of such a crew will certainly exist and lasting friendship will continue even

after retirement.

.

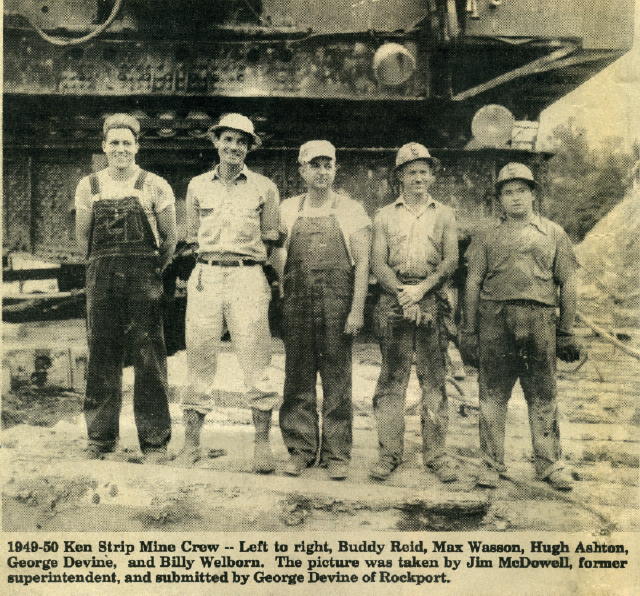

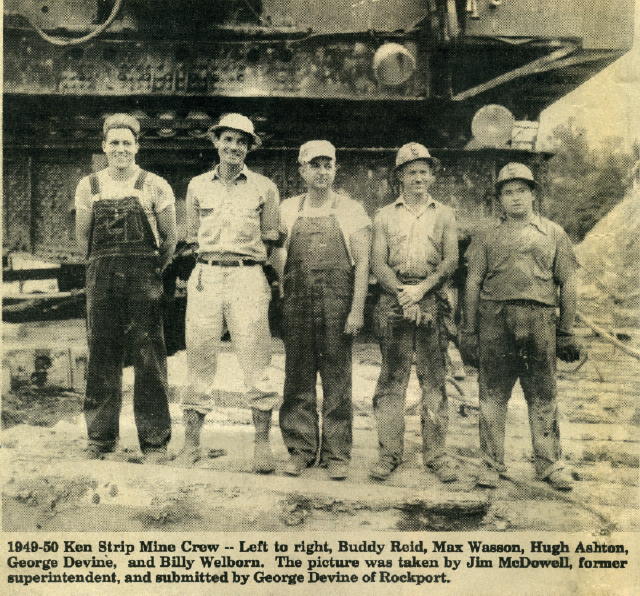

One such "Stripper Crew" is featured in this write-up. Buddy Reid, Hugh Ashton,

George Devine and Billy Welborn were mainstays at the Ken Mine and all lived and

raised a family close to each other and in the town of Rockport. Buddy, George,

and Billy were born, raised, and educated in Rockport. Hugh Ashton and his family

moved to Rockport soon after Ken Mine started operation. He hired in from the

Madisonville area and was considered an experience miner, while the other three

mentioned had to learn about mining and big machines. A "Stripper Crew", when I

was working at Ken Mine in The early sixties, consisted of only three people. The

"Operator" sat in the "Cab" of the shovel and pushed and pulled levers and foot

pedals to control the workings of the machine. The "Oiler" tended to the machine

and took care of the "Oiling and Greasing" needs as well as generally watched and

listened to the machine operation. A "Ground Man" worked on the ground around the

machine. Usually, he operated a "Bulldozer" and kept the ground area around the

"Stripper" free of boulders, rocks and other debris. This pictured "Crew" shows the

fourth person and I am not aware of what type position the fourth person held. In

the earlier years, a "Four Man Crew" may have been standard or the fourth person

may have been "Breaking In" or training for a new position. If any of you more

experienced miners know the answer or answers, please let me know.

I never knew Max Wasson, although I have heard many of the miners talk fondly of Max.

At the time the picture was taken, he may have been the "Pit Supervisor" or maybe

the assistant superintendent. Anyway, Max was just a nice guy according to all of

the people that I talked with. I am guessing, but I think that Max may have come

from the Madisonville area.

Now, not to be outdone, this "Stripper" crew was composed of great guys also. Buddy

Reid graduated from Rockport High School in 1944 and before he could catch his breath,

found himself in the middle of World War II. After the war, Buddy returned to Rockport

and soon found a job with Peabody Coal Company, Ken Mine. Buddy was the operator

of this "Stripper Crew" and I think that he started off with the BE 1050B Shovel.

He may have broken in with the Marion 40D, but my memory is him spending most of

his Ken Mine work time on the BE 1050B. Hugh Ashton was the "Ground Man" in this

crew. Hugh was just a good guy and he loved his work, thus he certainly could be

counted on to do his share of the work and more. George Devine was probably the

"Oiler" and he may have been training Billy on this position. George graduated

from Rockport High School in 1940 and tried his hand at several jobs, before he was

drafed into the Army. After being discharged, he became a Peabody employee and

eventually retired from Ken Mine. George just never wanted to keep any job for an

extended period of time and thus, he probably worked as many types of jobs at Ken

as anyone else. Billy graduated from Rockport High School in 1949 and he must have

gone to work at Ken the day after he graduated. Billy probably worked at Ken longer

than about anyone else. This must have been an elite crew as all of the men were easy

to work with and easy to get along with. I am sure that Ken Mine thought this crew

to be special. Of course, most of the miners at Ken Mine were special. That is why

it continue operation longer that most other mines.

Rockport, Echols, and Ohio County were fortunate to have Peabody Coal Company move

into the area. Prior to the nineteen fifties, good jobs were not very plentiful in

the area and those wanting a good wage for a day's work had to move north. Just a

small start at first developed into a major operation. Ken Mine alone may have

employed some four hundred miners at one time. Good jobs were plentiful and some

of the people that moved north were returning to the area where they were born and

raised. Rockport, Echols, and other towns in the area were on the move. Tax monies

were distributed to all of the area that was being mined and it seemed that this

source of monies was endless. Guess that the area thought that the "Boom" would

last forever, but once the coal, that was easy to mine was gone, the area feel on

more difficult times. By the start of the Twenty-First Century, "King Coal" was

gone and now the area that got used to "Easy Pickings" had a difficult time realizing

that the "Coal Boom" was over. It was a nice ride while it lasted.

See you.......

~jrd~

|