|

~~ River Queen Strip Mine! ~~

Peabody's River Queen Mine Office.

In 1956, Peabody Coal Company became partners with W. G. Duncan Coal Company

for a new mine in Muhlenberg County and River Queen mine was born. This new

mine was located west of Central City, Kentucky and mostly in an area bounded

by State Highway 70 on the North, County Road 175 on the West and the Western

Kentucky Parkway on the South. To the East, the mine area was almost to Central

City, to Powderly and neared Greenville. The supply of coal was plentiful and

this mine would continue operation for the next 35 or so years. Although the

mine was in Muhlenberg County, it would employ a lot of miners from Rockport

and Ohio County. Peabody would eventually buy out W. G. Duncan Coal Company,

but for several years, the mine was owned by the joint ownership and operated

by Peabody Coal Company.

After several years of operating out of small shelters for office and management,

a large office and maintenance complex was built. It was located near County

Road 181 and just to the South of Highway 70. Easy access to the mine area was

just a short drive for Central City and Greenville residents and not much farther

for the residents of Ohio and Hopkins Counties. A few years later, Peabody

decided to add to the Office/Garage/Warehouse area and built an office complex

for area management. The offices for the River Queen mine was on the second

floor and to the right of the complex. Divisional Offices were on the first floor

and to the right. The "Garage" was to the left and to the rear of the complex.

A large warehouse was in front of the garage. The tall building in the background

of the picture is a "Wielding and Large Equipment Shop". Peabody was expanding

by leaps and bounds and a new Divisional Office Complex was staffed. Management

of Peabody Western Kentucky Mines would now be controlled from this new compound.

In the mid nineteen-forties, Jackson Construction Company purchased some land in

the Echols, Kentucky area and walked a Marion 40D Shovel from Centertown to the

new mine. This small company was non-union and before any coal could be mined,

the United Mine Workers Of America established a "Picket Line" and the mine was

shut down. This "Strike" lasted some nine months and Jackson Construction Company

would not agree to union representation and sold the property to Kessler Brothers

Coal Company. Kessler Brothers Coal Company signed an agreement with the UMWA,

but before very much coal could be mined, sold the new Ken Mines to Peabody Coal

Company. In 1946 Peabody Coal Company became established in Ohio County and

signed an agreement with the United Mine Workers Of America. Now, a new era began

and coal mining at the Ken Mine could finally start.

After a few years of operation at Ken Mine, Peabody Coal Company must have

considered their investment to have been a good one. The area conditions were

favorable for mining the coal and of making a profit. The area work force

contained a lot of ex-veterans, most with a high school education, and they were

ready and willing to become good company employees. The young high school

graduates, from Rockport and other areas, were having to go north for work and

jumped at a chance for a local job. In the early fifties, Peabody started

opening a few more area mines. The River Queen Mine was one of these mines.

~~ BE 1650B "River Queen" ~~

Peabody's River Queen Mine Shovel-A BE 1650B.

When a "Strip Mine" is first started, a lot of mining equipment, as well as an

office complex, will eventually be built or purchased. A means of removing the

"Overburden" is one of the first needs. River Queen Mine started initial mining

operations in 1956 with a new BE 1650B, 55 Yard Shovel. This new shovel picked

up the name of "The River Queen" after the mine that built her. A few years

later, this 55 Yard shovel would seem small, but in 1956 with a new digging

shovel that large, this mine started off in grand form. All pieces of equipment

eventually "Wear-Out" and/or are severely damaged by misuse, by accidents, or by

metal fatigue and "Stripping Shovels" are no exception. This new shovel, in 1956,

operated several years before it had a "Boom Failure". After a boom failure to

a mine's "Stripper", doubt and uncertainty are on the mind of the miners. With

a "Can-Do" mentality, this massive machine was brought back to life in near

record time. Although the repair cost was in the neighborhood of a quarter of

a million dollars, this machine started digging again in about two weeks. After

operating for a little over 10 years at "River Queen", the BE 1650B was replaced

by a Marion 5960 Shovel. The BE 1650B was walked across Highway 175 to begin

operations at the Peabody's Vogue Mine. When the Vogue Mine was shut down, the

BE 1650B was then dismantled and sent to Peabody's Riverview Mine. From there,

it was sold to Green Coal Company. I think that is has since been scrapped.

~~ Marion 5960 "The Big Digger" ~~

Peabody's River Queen Mine Shovel-A Marion 5960.

This new Marion 5960-M shovel was a monster machine. The "Bucket" was a 125

Yard capacity behemoth and almost twice as large as the bucket on the BE 1650B

machine that it replaced. Guess one can see why it picked up the name of

"The Big Digger". From about 1969 until 1989, or a period of over twenty years,

this monster shovel became a leader in the removal of "Overburden". "The Big

Digger" was a very dependable machine. It was operated and maintained by experienced

miners. In 1982, it set a record for the "Best Run Time" efficiency by being

operational for 85% of the time. That record may still stand. In just one year(1982),

the year the "best Run Time" record was set, this huge machine stripped 178.11 acres.

Those acres consisted of 33,524,007 cubic yards of overburden being removed. That

figure is 1,046,778 tons of earth and rock. Impressive. Please note that this

"Spoil" was later reclaimed and today, a person can walk over the land that is habitable

for cattle and wildlife.

By the time the year 1990 rolled around, most of the River Queen coal reserves

had been depleted and it was time to close a very good mine that had been in

continuous operations for almost thirty-five years.

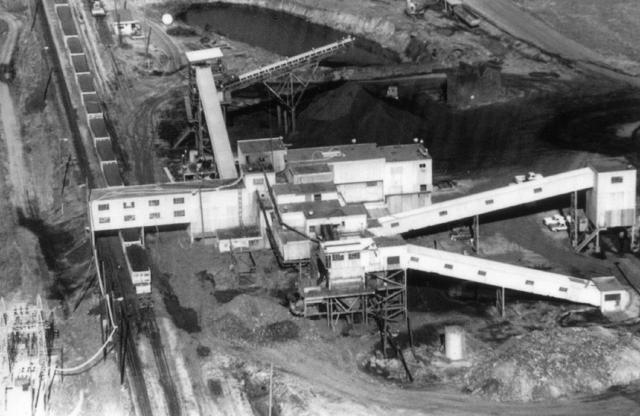

~~ River Queen Tipple ~~

The River Queen Tipple.

The River Queen Tipple.

The River Queen Mine was enormous in about every aspect. From the multi-purpose

office complex, to the large shovels and to the modern tipple, this mine was

somewhat different that all others. The tipple was a "Coal Processing" plant.

The raw coal, from the "Pit" area, was delivered by large trucks that could dump

their loads of coal, non-stopping, into the large underground hoppers. This

coal was then transported by belts to the "Wash Plant". The "Wash Plant" would

clean the coal, which would then be sent to hoppers, where it could be

transported, again by belts, to different shipping sections. The waste

byproducts were sent to a "Slurry Pit" where it was pumped via large pipes to a

"Slurry Holding Pond". With hoppers full of clean coal, a selection could be

made as to where to sent it out for shipment to customers. The main mode of

shipment was by River Queen's own railroad. River Queen built a railroad of

about ten miles that stretched from the "Tipple" to a "Barge Loading Facility"

on the Green River. The "Peabody Train" was built, operated, and maintained by

"River Queen" miners. Two, three, four and more loads a day were filled from

the tipple "Rail Loading" section and transported to the "Barge Loading"

facilities on the Green River. This train track was also tied into an outside

line where the could be loaded on other rail cars and shipped to anywhere in

the country. There was also a "Truck Hopper", but this was very seldom used.

At one time, a rail car was positioned under this hopper, and kept full of clean

coal, so the miners could purchase coal for home use.

~~ BE 270B Loader ~~

The BE 270B Loader.

River Queen Mine had an assortment of equipment that seemed to extend from one

end of the machinery scale to the other. I guess that all mines have, to a

certain extent, likewise conditions, but it seem that River Queen was more to

the extreme. This BE 270-B Loader is a fine example. A "Coal Loader" is a coal

digging machine, the function of which is to operate in the "Pit" and dig up the

coal that the "Stripper" has uncovered. In reality, they are smaller versions

of the strippers. The loader operates on the same level as the coal seam and

can load the "Haul Trucks", which can enter the pit on the coal seam or the

area where the coal has been dug. If a ten foot seam of coal is being loaded

and the haul truck is on top of the coal seam, the boom of the loader would

only have to reach to the top of the bed of the truck. For instance, if the

bed of the truck was twenty feet high and the coal seam was ten, it would take

a boom of thirty feet to load the truck. There was not that many ten foot coal

seams in the state of Kentucky, thus most of the loader booms were less than

forty feet in length. Are you getting ahead of me? Well, the boom on this

BE 270B Loader was a hundred feet in length. It was built in the fall of 1960

at the River Queen and operated there for a few years. It had a 9 Yard bucket

and that massive 100 foot boom. After about three years of operation, it was

"Walked" to Peabody's Vogue Mine and spent some time as a loader and some time

idle. The decision was made to remove twenty feet of the boom. Ten feet of

boom was cut off each end and in the early seventies, it was walked back to

River Queen and continued loading for several more years.

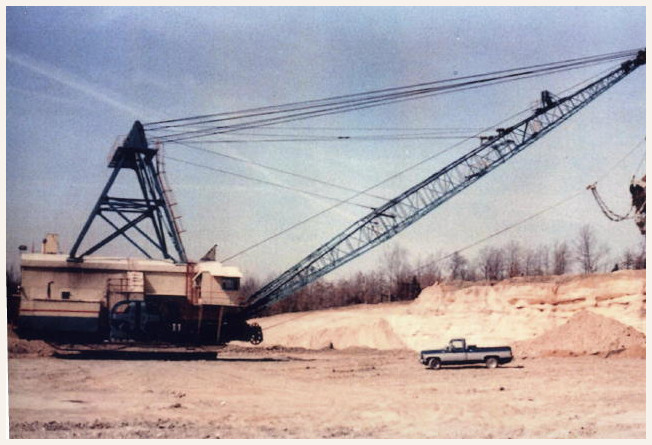

~~ Diesel Dragline ~~

The River Queen Diesel Dragline.

The River Queen Diesel Dragline.

Another machine that was not quite a normal "Run-Of-The-Mill" piece of equipment,

for a large strip mine, was the BE 450 W Diesel Dragline. In the forties, this

type of dragline would have been the norm, but in 1956 it was outdated. It was

just a little large too be used for digging ditches and a little small for stripping.

Regardless of whether it was out of place or not, it was certainly used at the

River Queen Mine. It was one of the first pieces to become operational at River

Queen Mine and one of the last to be shut down. The 450 W Dragline had a diesel

powered, locomotive engine and thus, was not limited in operation by an electrical

power source. There was some idle time, but for the most part, this old and

small dragline kept busy. A year or so before the mine was closed, this machine

was cut in half, loaded on large trucks, and crossed under Western Kentucky

Parkway. It was then welded back together and placed in operation where it stripped

on the South side of the parkway for several months. By now, River Queen had run

out of coal and a "Shut Down" mode was started. From 1956 until about 1990, a

period of almost 35 years, this grand old mine removed the coal from Western Kentucky,

help make a profit for Peabody Coal Company, provided a means for earning a living

for hundreds of coal miners, was a major source of revenue for Muhlenberg County,

and a main contributor for the economy of Kentucky as well as several counties

in the area. Countless small companies were started and most survived by providing

some type of a service to the River Queen Mine. The BE 450 W played a major part

in this overall operation. I think the old dragline was salvaged after the operation

on the South side of the Western Kentucky Parkway.

As always, if you are still reading this printed material, thanks for your time

and patience. Without any readers or lookers, this web page would be for naught.

:)

See you..........

jrd

|